I’ve worked with enough suppliers to know that going with the cheapest foundry is rarely worth it. What matters is how well they control the process, how consistent their results are, and how responsive they are to the needs of your production. When you’re sourcing critical aluminum components, your success depends heavily on your foundry’s precision, equipment, and experience. That’s why I pay close attention to their capabilities before making any recommendation.

I only suggest companies that I’ve vetted based on production methods, facility standards, technical knowledge, and ability to support different industries. One that clearly stands out is Alcast Company, and if you’re anywhere near Peoria, you’re not short on access to the right partner. You can find their casting foundry Peoria operation offering exactly the type of support and casting precision you want for both simple and complex jobs.

What Makes Alcast Company Worth Considering

Alcast isn’t just another aluminum foundry. They’ve been operating for over 50 years and have refined their approach to casting by investing in both talent and technology. They specialize in permanent mold aluminum casting, which is well-known for producing consistent, durable parts with a refined surface finish. For anyone in sectors like automotive or aerospace, that level of control is necessary, not optional.

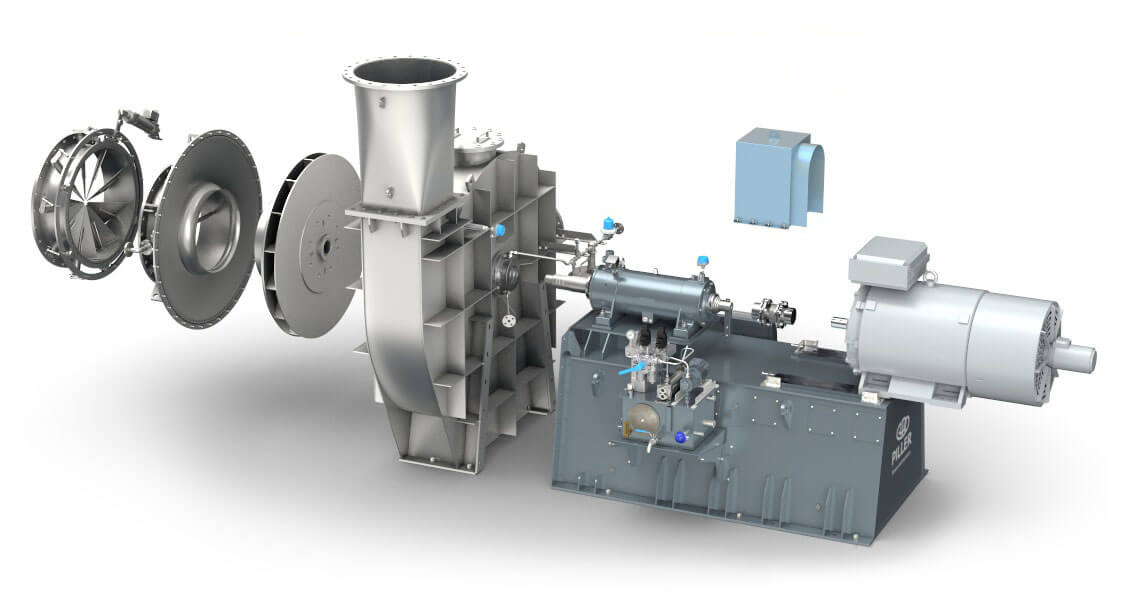

Their in-house capabilities are what I noticed right away. They handle everything—from machining to heat treating, powder coating, and even x-ray inspection—without outsourcing. That reduces the chances of delays, errors, or quality drift. You’re dealing with one team that manages your entire project, which is something I always prefer when reviewing foundries.

They also construct and maintain their own proprietary casting and core machines. That might sound like a technical detail, but what it really means is they control their own downtime and production flow. That translates to faster turnarounds, fewer disruptions, and lower costs on your end. For me, that’s a major advantage compared to foundries that depend entirely on third-party systems.

Why Their Process Matters

What I like about Alcast is how structured and thorough their process is. They incorporate CAD and simulation tools to map out casting before it begins. That allows them to identify and eliminate possible flaws before they become problems. It’s this type of advanced planning that saves you from rework, missed deadlines, or unreliable performance in the field.

They also apply finite element analysis (FEA) to their die design, which helps them anticipate how the part will behave under stress. That type of forward-thinking engineering is not always common in foundries, especially ones that only focus on volume instead of performance. If your components have structural or thermal requirements, that kind of preparation can make a difference in durability and compliance.

The cooling process is another area they manage carefully. For aluminum and even other metals like iron or steel, cooling dynamics directly affect hardness, finish, and strength. Alcast adjusts their methods to suit each alloy they work with, which shows they’re thinking about long-term performance—not just getting the part out the door.

Their Experience Adds Real Value

Some companies have years in the industry but still don’t modernize. Alcast isn’t one of them. Their facility in Peoria combines experience with constant upgrades. They’ve adapted to changes in materials, design software, and customer expectations without losing sight of the basics. That balance between innovation and fundamentals is something I look for when evaluating foundry partners.

You’ll also notice how broad their industry reach is. Whether you need parts for a vehicle, machinery, or industrial system, they have systems in place to manage both short-run prototypes and large-scale production. This flexibility is important because not every job requires high-volume manufacturing. Sometimes you need a custom mold made for a limited run, and they can accommodate that without sacrificing precision.

Why I Would Choose Alcast Company Again

If you need a foundry that will support your engineering team, meet spec tolerances, and stay on schedule, Alcast is one I’d trust. Their process is tight, their equipment is modern, and their experience is deep. I’ve seen enough casting operations to recognize when a company is running a controlled, quality-first operation—and that’s what they’re doing.

They’re not relying on shortcuts or outsourcing key steps. They’re building parts from the ground up, using their own machines, their own people, and a clear plan at every stage. That’s how you avoid setbacks and guarantee consistency.

For any project that requires permanent mold aluminum casting, I’d say Alcast is a strong choice—especially if you’re sourcing locally in Illinois. With their control over cost, time, and quality, it’s hard to make a better decision for your casting needs.

Comments