In the current industrialized world, the world is fast-paced, the only way to have efficiency, reliability, and sustainability is through Centrifugal blowers and compressors. The machines are applied in the industries including manufacturing, HVAC, wastewater treatment, petrochemicals, and power generation making it a pillar in contemporary operations.

What do Centrifugal Blowers and Compressors mean?

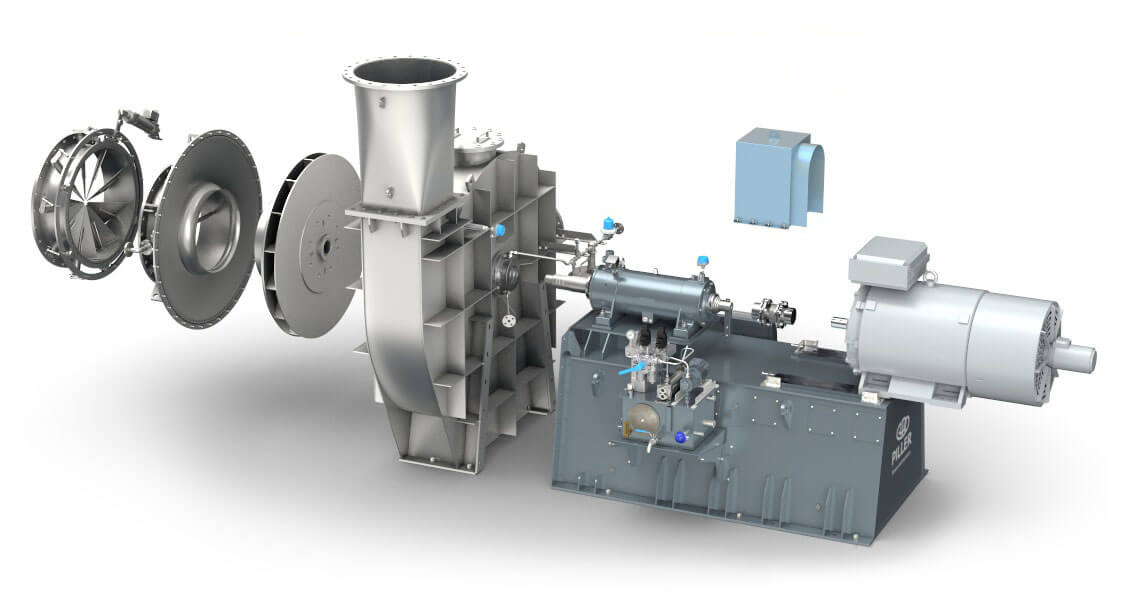

Turbomachinery is centrifugal blowers and compressors, which use centrifugal force to accelerate the velocity of air or gas and its pressure. A blower is unit created to convey large amounts of air with a relatively low pressure whereas a compressor is created to provide high pressures, which are needed in more intensive processes. They both use fast turning impellers that are used to produce pressure energy that can be used.

Important Industrial Applications.

- Manufacturing & Production:

Centrifugal blowers and compressors support the smooth operation of the cooling systems, pneumatic conveyor, and other operations in line with reducing the downtime and maximizing output.

- HVAC Systems:

These machines are part of heating, ventilation and air conditioning which guarantee the uniformity of air supply, the quality of air inside, and the energy-efficient control of the climate.

- Wastewater Treatment Facilities:

Oxygen in aeration tanks is provided by blowers and this facilitates microorganisms that decompose organic waste. Compressors assist in the maintenance of pressure in pumping and distribution systems.

Compressors are used in the high-pressure gas transportation, and blowers provide combustion air, so they are important in refining, gas processing, and energy generation.

Centrifugal Blowers and Compressors have benefits.

- Energy Efficiency: Sophisticated designs consume less energy which cuts costs and environmental footprint.

- Durability and Reliability: They are designed to be operated continuously and hence have long service life with low downtimes.

- Minimal upkeep: Some of the models do not need much maintenance and this saves time and repairing costs.

- Scalability: Can be used with small-scale facilities or industrial-scale plants that are customized.

Industrial Air and Gas Handling in the Future.

With the increasing trend in industries towards sustainability, centrifugal blowers and compressors are developing intelligent technology, variable speed drives, and improved aerodynamic designs. The innovations are not only beneficial in terms of performance because they help businesses to lower their carbon footprint and comply with regulatory requirements.

Conclusion

Centrifugal Blowers and Compressors in the modern industries have more than just a functional purpose, as they are the key to the effectiveness of operations, safety and environmental accountability of operations. The main concern of companies that want to improve productivity and sustainability should be the investment in the equipment of high quality and energy efficiency aimed to cope with the challenges of the modern industry.

Comments