A compressed air system is only as reliable as its method for removing the water, oil, and particulate that collect as byproducts of compression. Left unchecked, condensate steals capacity, corrodes piping, and contaminates end products—all while forcing compressors to work harder than necessary. This article clarifies how condensate forms, why drains are essential, and which mechanisms best balance reliability with energy efficiency. You’ll learn the differences between manual, timer-based, float-operated, and zero-loss models, plus the maintenance practices that keep them functioning day after day. Along the way, we’ll connect these choices to real operating impacts like pressure stability, air quality, and downtime reduction. Whether you manage a small shop or a sprawling plant, the practical steps here will help you get more from your equipment, including solutions trusted by PneuTech and other industry leaders.

How Condensate Builds Up in Compressed Air Systems

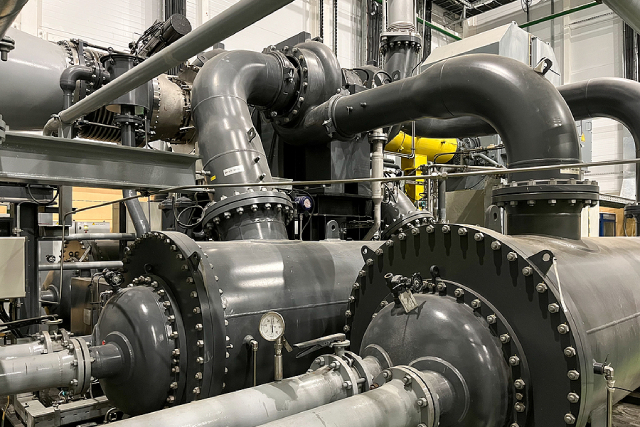

Condensate is an inevitable outcome of compressing ambient air; as pressure rises and temperature changes, water vapor reaches its dew point and drops out of the air stream. The resulting liquid often mixes with compressor lubricant and airborne contaminants—fine dust, rust particles, or hydrocarbon residues—creating a corrosive emulsion. This mixture accumulates at common low points: aftercoolers, receiver tanks, drip legs, filters, dryers, and at the far ends of distribution lines. Seasonal humidity swings can amplify the volume dramatically, especially in warm, moist climates where incoming air holds more water. Without consistent drainage, pockets of liquid constrict flow, elevate pressure drop, and increase the risk of carryover to tools and processes.

Where condensate tends to collect and why it matters

The journey through an air system creates multiple opportunities for condensation as air cools after compression and during distribution. Aftercoolers remove heat rapidly, causing a surge of condensation; receiver tanks then act as both a buffer and a settling point for liquid. As the network branches, low points and dead legs capture residual moisture that gravity can’t move, making these spots prime locations for drain installation. Filters and dryers trap aerosolized droplets and contaminants, but they also rely on effective drainage to prevent saturation and breakthrough. The cumulative effect of small puddles is significant: even minor liquid blockages can force higher discharge pressures to satisfy demand, wasting energy while accelerating wear on pneumatic components.

Automatic vs Manual Drains: Choosing the Right Mechanism

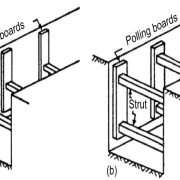

Manual drains seem simple, but they depend on disciplined routines and the availability of staff who remember to open them at the right time, for the right duration. In practice, manual routines often slip—especially on night shifts or during peak production—allowing condensate to pool until it breaks through filters or floods receiver tanks. Automatic alternatives reduce this variability by opening on a schedule, in response to a float, or based on actual condensate level. Timer drains are inexpensive and easy to retrofit but can waste air if set too long, while float drains open only when liquid is present, minimizing purge losses. The best mechanism depends on your air demand profile, condensate volume, and tolerance for maintenance.

Selection criteria for drain mechanisms

- Duty cycle: Systems with variable demand benefit from demand-responsive drains to avoid purging air during low-load periods.

- Condensate composition: Emulsified oil or debris may clog small orifices; choose larger flow paths or self-cleaning designs if contamination is heavy.

- Accessibility: Remote or elevated locations favor automatic drains with test buttons or local indicators to confirm operation.

- Energy priorities: Facilities targeting energy optimization may prefer zero-loss or float drains over basic timer valves.

For many facilities, the ideal setup blends technologies: float drains at key collection points like receivers, timer drains on legacy filters where wiring is difficult, and a centralized approach for high-volume separators. When evaluating options, review the flow capacity, minimum operating pressure, and maintenance tasks required to keep the valve functional. Choosing Condensate Drains PneuTech offers through authorized channels can standardize parts and simplify service across multiple sites. A consistent, automatic strategy turns drainage from a recurring chore into a predictable process that supports stable, efficient operation.

Zero-Loss Drains and Their Efficiency Benefits

Zero-loss drains open only when liquid is present and close before compressed air escapes, using capacitance probes, optical sensors, or smart float designs to distinguish condensate from air. The result is straightforward: you purge water, oil, and contaminants while preserving system pressure, instead of venting valuable compressed air. In high-duty systems, this difference is measurable as lower compressor runtime, reduced cycling, and less wear on motors and dryers. The consistent removal of liquid also protects downstream filters from saturation, preserving filtration efficiency and extending element life. For plants chasing energy KPIs or rebates, zero-loss drains can be a practical lever with fast payback.

How zero-loss drains deliver measurable returns

Zero-loss technology minimizes the “hidden tax” of timer-based purges that vent air even when no liquid is present. By activating only on demand, they prevent unnecessary pressure fluctuations and reduce the chance of water carryover during periods of heavy condensation. Modern designs include self-cleaning cycles, alarm outputs, and manual test functions for easy verification without disrupting production. These features translate into fewer surprises—no flooded receivers after a hot day, no dribbling valves wasting air overnight, and fewer emergency maintenance calls.

From an accounting perspective, savings compound through lower energy costs and postponed equipment replacements. Facilities standardizing on Condensate Drains PneuTech recommends for critical points often report steadier pressure at the far ends of their networks, which improves tool performance and quality consistency. Pairing zero-loss drains with an oil/water separator completes the chain, allowing proper disposal while staying on the right side of environmental rules. With guidance from PneuTech service teams or equivalent specialists, plants can match drain size and sensor logic to real condensate loads and ensure the hardware performs reliably.

Common Problems Caused by Poor Condensate Management

When condensate isn’t removed consistently, it becomes a system-wide liability. Water collects in receivers and lines, forcing compressors to run at higher pressures to overcome losses, which raises energy consumption. That moisture accelerates corrosion, producing scale and rust that migrate downstream and clog regulators, valves, and orifices. Filters saturate faster and can bypass when overwhelmed, sending liquid into dryers or onto production equipment. The outcome is familiar to many operators: pressure swings, quality issues, and unplanned downtime.

Warning signs to watch before problems escalate

Look for these indicators during daily and weekly checks:

- Visible water at drain outlets long after a cycle has completed.

- Unusual pressure drops at known bottlenecks or far-line locations.

- Frequent filter changes or discolored filter elements well before expected intervals.

- Water spotting, lubricant emulsions, or rust residue at point-of-use tools.

- Dryer high-load alarms or increased purge rates on desiccant units.

These symptoms aren’t just maintenance headaches; they drive tangible costs. Product contamination can force rework or scrappage in food, pharma, coating, and electronics applications. Environmental risks emerge when oily condensate is discharged without proper separation—violations that can lead to fines and reputational harm. By integrating robust drains, such as the demand-activated models common in modern packages and those aligned with Condensate Drains PneuTech best practices, facilities maintain clean, dry air and avoid the cascading failures that begin with a single neglected drip leg.

Routine Drain Maintenance to Prevent System Downtime

Even the best drain will falter without routine checks, especially in systems with heavy oil carryover or particulate. A practical program schedules inspections at receivers, aftercoolers, prefilters, refrigerated dryers, and any low points or dead legs that tend to accumulate moisture. Verify operation using test buttons or manual overrides, and listen for excessive air loss that indicates an orifice stuck open. If a drain clogs frequently, investigate upstream causes: failed coalescing elements, degraded compressor separators, or line debris. Capturing these findings in a simple log helps spot patterns before they disrupt production.

A practical maintenance checklist for reliable drainage

- Weekly: Test automatic valves, empty manual drains in less-trafficked areas, and inspect sight bowls for emulsions or sludge.

- Monthly: Clean strainers and inlet screens, confirm electrical connections on electronic drains, and verify that alarm outputs report correctly.

- Quarterly: Replace seals as needed, check float movement, calibrate sensors on zero-loss models, and ensure the oil/water separator isn’t overloaded.

- Seasonal: Re-tune timer settings or sensor sensitivity to match humidity swings, and add drains to new low points created by line modifications.

Standardizing parts and procedures simplifies training, speeds troubleshooting, and reduces spare inventory. Selecting Condensate Drains PneuTech supplies for critical points can ensure compatibility across varied equipment, especially in multi-facility operations. Keep a spare drain kit on hand for key assets—receiver tanks and primary filters—so repairs don’t wait for shipments. Finally, tie drain performance to KPIs like pressure stability, energy per cfm, and filter life; this keeps the maintenance team focused on outcomes rather than tasks. With clear accountability and support from partners like PneuTech, you transform drainage from an afterthought into a reliable safeguard for uptime and air quality.

Comments